|

|

Maksan Makina Tekstil San. ve Tic. Ltd. Sti.

Address: Sanayi

Sitesi No:1, 09650 Atca-Nazilli-TURKEY

Tel: +90.256.356 33 01

Fax: +90.256.356 31 11

e-mail: mail@maksan-tmc.com.tr

Web:

www.maksan-tmc.com.tr |

|

|

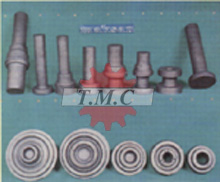

FORGING

In our forging unit open type, close type can be made from 100g to 8kg.

Furthermore, partial heaping up works can be done up to 100kg. Various capacities of

friction presses, excentric presses, pile-drivers, heating ovens, normalisation ovens

exist in our forging unit.

HEAT TREATMENT

We have a gas carburising unit with an atmosphere controlled machine in our heat

treatment unit. In this unit we produce both at our own account and for other enterprises,

in 400kg charge capacity ovens. All kinds of quenched and tempered steel-, case-hardening

steel-, hot-work tool steel- (die materials) and induction hardening steel heat treatment

can be done in this unit.

GEAR HOBBING and

GLEASON & OERLIKON HYPOID SPIRAL BEVEL GEAR SYSTEM

Our gear hobbing unit works with cutting edge automatic continuous-feed machines.

All kinds of helical, spur, bevel and hypoid gears are produced. We are producing the

hypoid and spiral bevel gears with GLEASON and OERLIKON System. Our straight bevel gear

diameter up to 700mm. Our capacity for gear hobbing is up to a gear diameter of 1400mm for

internal/external gears of a size up to 300mm. We can also produce spur and helical gears

of a module between 0,5 (Dp 50,8) and 20 (Dp 1,27).

BOHRWERK SHOP

Maksan Gear can produce big gearboxes and machine

bodies for machine industries.The diameter of cutter shaft of Bohrwerk is 105mm.

Especially these gearboxes and machine bodies are producing for cement plants, mine

machines, electrical cable machines, chemical plant machines and etc. Besides new

gearboxes, we can also work for overhauling the gearboxes.

CNC MACHINING CENTER and

CNC TURNING SHOP

Maksan Gear can produce moulds and models for

plastic injection machines and hot or cold forging machines with CNC Machining Centers.

The weight of machined part can be up to 1500 kg. Besides machining of moulds and models,

we can also serve for high quantity parts for automotive and machine industries. With CNC

Turning machines, we can serve about high quantity turning parts.

QUALITY

CONTROL

Maksan is applying a total quality management policy. With respect to all our products, we

pay attention to a faultless production, within normal limits of tolerance. For this

purpose we use various kinds of statistics and we also consider staff education important.

QUALITY

POLICY

Maksan Disli Makina Tekstil San. ve Tic. Ltd. Sti. has become a leading expert in gear production. The quality of our

products and the satisfaction of our clients is the key to our continuous success.

By establishing a quality control system that

aims at the totality of the management we can ensure the highest standards of quality,

productivity, flexibility and client satisfaction, at the same time keeping expences low.

In view of these aims, the leading principles of our quality policy are:

To ensure the clients' complete

satisfaction, Continuous improvement of the product

quality and diminishing of expences through the joint efforts of all our personnel,

Supplying clear and unambiguous instructions to contractors

working for us, To ensure a planned and systematic

framework for the improvement of the quality, taking the clients needs as a starting

point, To continuously arrange education programs for

our employees, To protect the environment and to use

exhaustible resources in a responsible way, To do all

our works correctly the first time and always, and To

ensure the continuity of the quality improvement works.

Our aim is to give the responsibility of this policy to all

of our employees and to make sure our quality standards are understood by everybody and

that works are arranged in accordance with these standards.

|